Warrensville to Westferry: Lessons in Light Rail

What London and Cleveland's new rolling stock can teach North American rail systems

The Docklands Light Railway in East London is about to get fifty-four new toys. Entering service from 2024, the new vehicles continue the DLR’s proud tradition of stretching the defintion of light rail in pursuit of greater capacity.

The six previous generations of DLR trains have been pretty much standard 29m-long articulated light rail vehicles, running in two- or three- car sets. Third rail power and automated operation set them apart, but otherwise the cars resemble other LRVs.

These are flexible and easily procured, but space is wasted in between coupled cars. The couplers and control panels take up about a metre of length; those in between cars occupy about 5% of a three-car train.

To eke out more usable saloon space, the new trains are 87m walk-through units. TfL claim a 10% capacity increase compared to their predecessors. The other 5% will come from an optimised interior layout with more space for standing passengers.

The new vehicles belong to Spanish manufacturer CAF’s Inneo platform, alongside recent rolling stock for metro systems (heavy rail in North American parlance) in Rome, Quito, Istanbul and others. With its new high-capacity trains and two-minute core headways, East London’s light railway is very much growing up into a light metro.

Imported German Cars

Globally, just about any light rail vehicle you find will probably be an articulated car measuring 2.65m wide and either 24m or 28-29m long, capable of navigating 25m turn radii. This de facto LRV standard, or pair of standards, can be traced to the German cities of Frankfurt and Cologne.

As the two cities grew in the 1960s, both opted to move the busy downtown sections of their tram systems into new underground tunnels, pioneering the stadtbahn model. Rather than the conventional trams of the North American surface-subway systems, the Stadtbahns would use modern vehicles able to serve high platforms, with folding steps for existing low-platform tram stops.

Duewag, the dominant manufacturer of West German trams, produced the 24m articulated U2 vehicle for Frankfurt. It would export the design to San Diego, Calgary and Edmonton. For Cologne, meanwhile, Duewag built the slightly longer 28m articulated Stadtbahnwagen B. Both were of a 2.65m width matching Berlin’s large profile U-Bahn lines, close enough to a 2.5m-wide tram to fit existing infrastructure.

Neighbouring cities of the Ruhr metropolitan region also ordered the Stadtbahnwagen B; the thus widespread design became something of an export product. It’s the basis of vehicles on Britain’s three late 80s/early 90s rail systems: The DLR, the Tyne and Wear Metro, and the Manchester Metrolink.

Siemens, by then owning the majority of Duewag, would manufacture cars derived from either the Frankfurt or Cologne designs for most of that era’s North American LRTs. Their 24m-long S200s and 29m-long S70/S700s dominate the current North American market, but its dimensions are also the standard to which the international market builds.

Meanwhile, in Cleveland

When it comes to serious Cleveland vibes, a decaying and corroded fleet of railcars relying increasingly on cannibalised spare parts can join a river catching fire or a respected writer on deadly North American road design demanding that teachers be exposed to infectious disease.

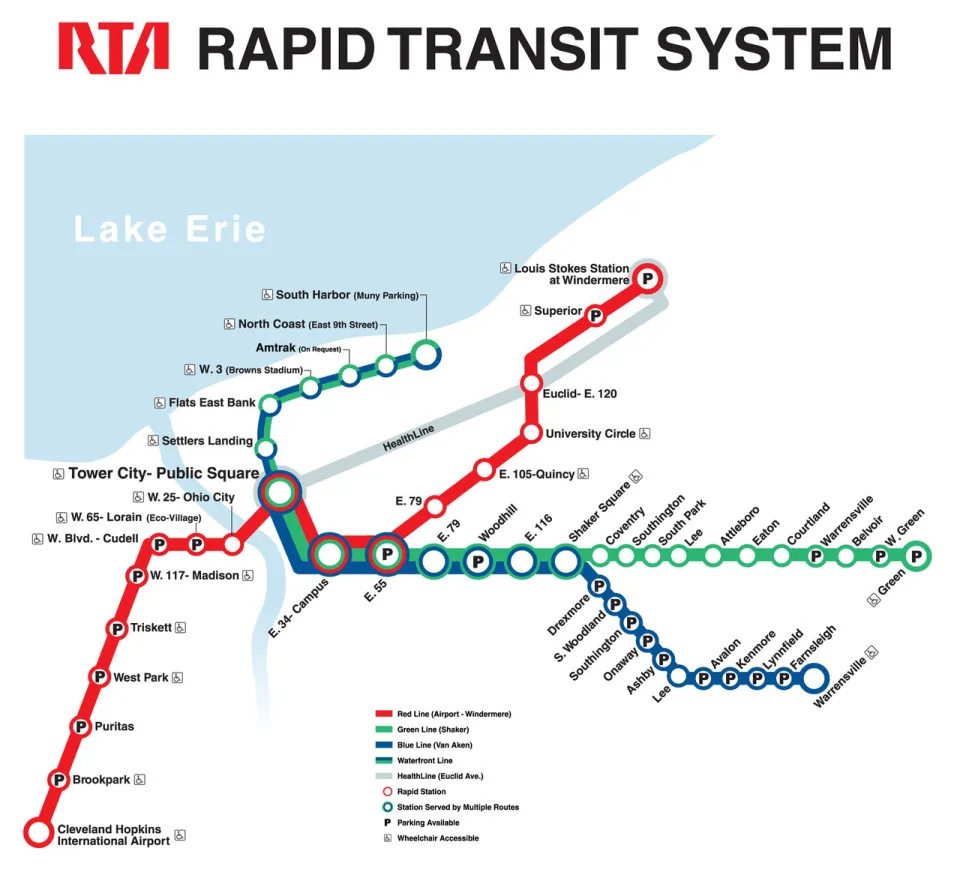

Cleveland’s rail system comprises a 1920s tramway (the Green and Blue Lines) and a 1950s heavy metro (the Red Line). The two share tracks for a 5km segment alongside the main line railway between downtown Cleveland and the western neighbourhood of Kinsman, originally constructed as an express tramway in the 1930s.

Having been designed around sharing tracks, the Red Line uses overhead rather than third rail power. The intermediate stations at 34th and 55th Streets have platforms with both high and low sections; Tower City station has seperate heavy and light rail tracks.

Faced with the need to replace both fleets, Cleveland’s transit agency is procuring a unified fleet of high floor Siemens S200 LRVs with folding steps—descendents of the Frankfurt U2 cars. Thus Cleveland are turning their system into a classic Stadbahn. For the Red Line it’s theoretically a downgrade in capacity, but that’s not a concern on a line serving fewer than three million annual trips with two-car trains every fifteen minutes.

The S200s’ narrower size compared to 3m-wide heavy rail cars will require slightly extended Red Line platforms, as well as slightly raising tracks to accomodate their lower floor height. But compared to maintaining two micro-fleets, they’ll offer easier maintenance and operator training, and being a standard design they’ll make this and every future procurement easier.

The real clincher for the unified fleet was that the single cars making up the current Red Line fleet have become obsolete in favour of married pairs, the ~40m length of which can’t fit the RTA’s maintenence bays. The $19 million cost of adapting the Red Line for LRVs is a bargain compaired to either rebuilding the maintenence facility, or procuring small orders of non-standard cars forever.

Accessibility at low platforms will be ensured by means of the existing mini-high platforms allowing level boarding at one door, though these are yet to be added at many light rail stations. It’s worth noting that German cities are now moving towards providing high platforms throughout to provide easy boarding at every door. Hopefully Cleveland can eventually follow suit.

Consulting a Medium-Capacity System

The urban rail systems of the USA and Canada have two genders: Light rail of the kind we’ve discussed, and heavy rail. The latter are distinguished by their full grade separation and also generous scale: Accomodating vehicles typically 3m wide and around 23m long, arranged in married pairs.

Heavy rail of this kind can carry 30-40 thousand passengers per hour per direction (pphpd). But aside from the Washington Metro and BART, the capacity of actual peak time train lengths and headways on the USA’s postwar heavy and light rail systems—service capacity, let’s call it—never gets above 20k pphpd.

So in terms of service capacity, you have a whole lot of medim-capacity systems: The intentionally vague category between a 5k pphpd conventional tramway, and a 30k pphpd high-capacity metro.

For example, Miami has a heavy rail system good for 30k pphpd, and runs 12 trains per hour of 91m length (four of the six cars platforms can fit). Seattle, meanwhile, has a light rail system good for 20k, and runs 10 trains per hour of 116m length (the four LRVs that platforms can accomodate). Thus both have a peak service capacity of approximately 8,000.

For comparison, peak service capacity of the DLR between Shadwell and Westferry is presently approximately 18k pphpd with 30tph comprising two- and three-car trains. A fleet entirely comprising the new walk-through units would bring that to 23.7k.

Seattle and Baltimore

The thing about being in that medium capacity range is that cities aren’t constrained by the mode they initially chose to build to the extent they might imagine. It’s perfectly possible to adapt its existing infrastructure to meet its needs over the coming decades.

Or, if you’re Seattle or Baltimore, you can dig entire new downtown tunnels to address the assumed constraints of your existing rail system. Both will get their own article in the coming weeks (subscribe for that), but here’s the short version.

Seattle’s second downtown light rail tunnel, presently in planning, accounts for most of the projected $12.6bn cost of expanding the system to serve West Seattle and Ballard. This in the context of a $6.5 billion funding shortfall at Sound Transit which might push some 2030s extensions into the 2040s. The 30 to 60 metre depth of stations will add two or three minutes to riders’ trips.

It was pursued on the basis that the existing network maxes out at 12k pphpd: A standing load of 600 on 116m, four-car trains every three minutes (20tph). The new tunnel will serve the South Link route, limited to six-minute headways by its street segment. Thus the two tunnels together get us to 30tph, or 18kpphpd.

But this number could be accomodated by the 90-second headway signalling in the existing tunnel permits. San Francisco’s Muni Metro has managed similar headways. A difficulty is station dwell times, given sub-optimal passenger flow on low floor LRVs.

Adapting the system for high floor, walk-through LRVs would involve some infrastructure work, but two orders of magnitude less than a new tunnel. As well as reducing dwells, these would gain the 10% of length current four-car LRV sets occupy with buried cabs and couplers. A 116m version of the DLR’s CAF trains would enable a crush loading over a thousand. Even at more comfortable loading and a 2.5 minute headway, one tunnel can exceed 20k pphpd.

Baltimore, meanwhile, is studying a revival of its East-West rail project, cancelled in 2015 by then governor Larry Hogan to redirect funds to roads for his suburban voter base. The cancelled project and some of the options being studied are light rail, and include a new downtown tunnel one (1) block away from that of the existing but incompatible heavy rail Metro.

Other options involve a slow surface alignment downtown, directly above the existing Metro. A heavy rail option does share Metro tracks between Lexington Market and Johns Hopkins Hopsital, but has the highest projected costs despite a shorter route in the West and a less populous alignment along a railroad corridor in the East.

Unlike Seattle’s light rail, Baltimore’s Metro has no capacity problem. In the years prior to 2020, it typically got just under 40,000 weekday riders, less than some bus routes. It’s recovered fewer than a quarter since 2020. Part of the difficulty is that the high cost of extentions built to heavy rail standards preserves the 1983 system in amber. A ‘downgrade’ to a more scalable technology might be no bad thing.

This could look like Cleveland’s standardisation on high floor LRVs, allowing East-West light rail to flow into the downtown tunnel in Stadtbahn fashion. It could also look like adopting modern automated light metro technology to make grade-separated extensions more affordable. In Copenhagen, for example, trains are short (48m with provision for 60m) but very frequent. This enables the use of modest cut-and-cover statons that fit within existing open spaces, reducing the high cost of subterranean stations.

Digging Holes

I’m sure I’m the first humanties grad ever to propose that two categories may be more fluid than they appear. This isn’t to diminish the importance of a grade-separated heavy rail infrastructure. If there’s half a chance of a city needing that capacity, it shouldn’t start introducing street running or sharing with main line trains.

There’s also good reason for an entirely new system to be fully grade-separated and automated so that trains can run frequently at all hours. But where there’s an existing transit infrastructure, it should be an opportunity rather than a constraint. As long as you’re working with steel-on-steel and at least the loading guage of a tramway, modern rail systems can be adapted for either scalability or capacity.

It’s often easier for many decision makers to replicate the Independent graphic of Bin Laden’s supposed underground lair beneath Grand Central than to figure out a long-range plan that creatively utilises existing assets. So as ever, it becomes the transit advocate’s job to assert that better things are in fact possible.